1�、 Product Introduction

LSD electroplated copper grounding electrode is a special electroplating technology that uniformly covers 99.9% pure copper onto a low-carbon steel core, allowing copper to be completely molecularly combined with the steel core (if the two are not tightly combined, under the condition of electricity, a primary battery reaction will occur, and the anode metal iron will undergo oxidation reaction to become iron ion loss, which will accelerate the corrosion of the steel core). It has the characteristics of copper layer thickness (above 0.25 millimeters), good adhesion, and non stripping (can roll threads). Its advantages are high tensile strength (up to 600 Newtons per square millimeter), strong corrosion resistance (ensuring a service life of over 50 years), constant low resistance, and good plasticity. It has both the same performance as copper and the characteristics of steel.

LSD electroplated copper grounding electrode has strong protection against both natural corrosion and electrochemical reactions after being deeply buried underground. LSD electroplated copper grounding electrode and grounding connection use our company's hot melt welding powder for exothermic welding, so that the grounding device is completely protected by copper and becomes a truly maintenance free grounding device.

LSD electroplated copper grounding electrode is equipped with coaxial connectors, drive heads, drill bits, and other accessories. According to different geological and usage requirements, the length of LSD electroplated copper grounding electrode can be arbitrarily increased by using brass coaxial connectors (connecting bolts) for connection. The end is connected by a driving head (connecting bolt) for striking when LSD electroplated copper grounding electrode is deeply penetrated. The end is connected with a specially designed drill bit (connecting bolt) to facilitate deep drilling of the rod. Widely used in power plants, substations, transmission line towers, communication base stations, airports, railways, various high-rise buildings, microwave relay stations, network rooms, petrochemical plants, oil storage tanks and other places for lightning protection grounding, anti-static grounding, protective grounding, working grounding, etc.

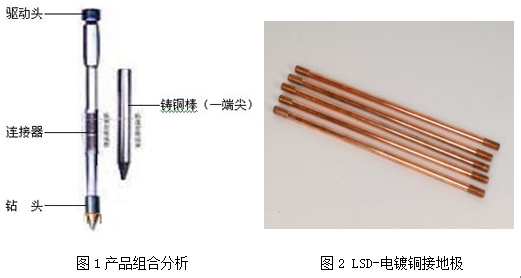

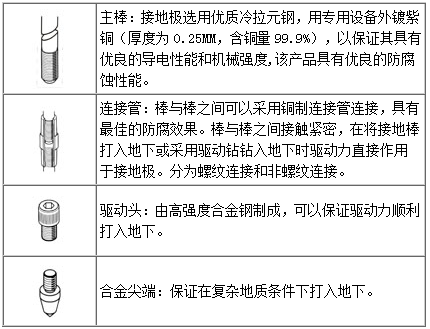

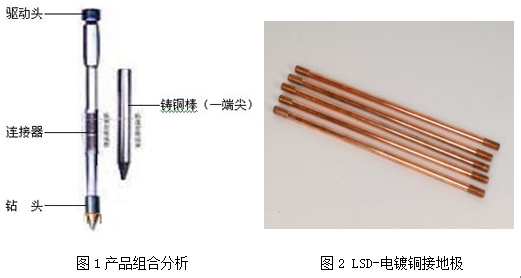

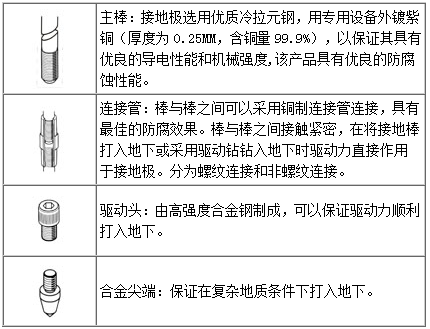

Product diagram annotation: (Figure 1): The left is the LSD electroplated copper grounding electrode combination diagram, and the right is the 1-meter long (pointed end) HT electroplated copper grounding electrode. LSD electroplated copper grounding electrode (see Figure 2) can be connected to a drill bit at the bottom (as shown in Figure 4), or to a HT electroplated copper grounding electrode at one end. The other end can be connected to the drive head in Figure 3.

In developed countries, electroplated copper materials have been widely used in grounding devices due to their good conductivity, high mechanical strength, and especially the excellent corrosion resistance of the externally coated copper layer. In relevant standards, countries such as the United States, the United Kingdom, and Germany stipulate that both grounding bodies and grounding wires can be made of electroplated copper composite materials. In China, the anti-corrosion and reliability of grounding devices have been increasingly valued, and electroplated copper composite materials have been used as a substitute

LSD electroplated copper grounding electrode is developed based on the reference of foreign technology. It has the advantages of good conductivity, low resistance, strong corrosion resistance, easy installation, and good electrical connection performance. It can be widely used in grounding devices for power transmission and communication lines, power stations, buildings, and antennas. It can also be used in grounding systems for electronic equipment such as computers, and can be combined with lightning arresters (lightning rods, lightning conductors) and down conductors to form lightning protection grounding devices.

2、 Product advantages:

1. Unique manufacturing process: adopting the domestically pioneering electroplating production process to achieve molecular bonding between copper and steel. It can be pulled freely like pulling a single metal, without detachment, warping, or cracking.

2. Superior anti-corrosion properties: The composite interface adopts molecular bonding, with no residue and no corrosion phenomenon on the bonding surface; Strong corrosion resistance, long service life (over 30 years), and reduced maintenance labor intensity.

3. Better electrical performance: The excellent conductivity of the surface copper material makes its own resistance value much lower than conventional materials.

4. Widely applicable: This product is suitable for grounding construction under different soil moisture, temperature, pH value, and resistivity changes.

5. Safe and reliable connection: using dedicated connecting pipes or hot melt welding, the joints are firm and stable.

6. Easy and fast installation: With complete accessories and convenient installation, it can effectively improve construction speed.

7. Improve grounding depth: With a special connection transmission method, it can penetrate up to 35 meters underground to meet the low resistance requirements of special occasions.

8. Low construction cost: Compared to the traditional construction method of using pure copper grounding rods and grounding strips, the cost has been significantly reduced.

Main technical parameters of LSD electroplated copper grounding electrode

u The thinnest thickness of the copper layer is ≥ 0.25mm

u Tensile strength ≥ 600N/mm2

u Flatness error ≤ 1mm/m

u Copper layer plasticity: When the grounding electrode (wire) is bent 90 degrees, there are no cracks on the inner and outer edges of the bend

u Copper layer adhesion: According to the adhesion test, except for the peeling copper layer at the bite of the tiger pliers, the copper steel adhesion in the rest of the parts is good and there is no peeling phenomenon.

The grounding electrode can be connected to the required length and can penetrate up to 30 meters underground without being affected by any climatic conditions that may increase soil resistivity and grounding resistance, such as frost and drought.

3�、 Model/Specification:

LSD electroplated copper grounding electrode has two structures: standard type and combination type:

Standard type: Single LSD electroplated copper grounding electrode, with one end cut at a 60 degree angle and the other end cut flat and truncated.

Combination type: a grounding body composed of multiple LSD electroplated copper grounding electrodes connected by threaded connectors. Used for deep grounding, with a maximum depth of 35m. Both ends of a single LSD electroplated copper grounding electrode are rounded and chamfered to provide a force surface for insertion into the ground.