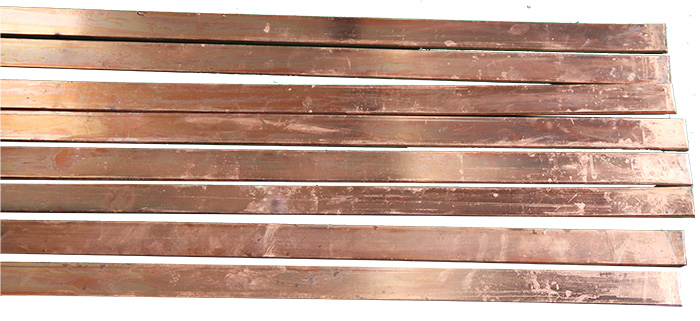

1. Long service life: Copper plated steel grounding material utilizes the anti-corrosion properties of a copper layer with a surface thickness of up to 0.254mm, and adopts a molecular permeation electroplating process to enhance the bonding between the copper layer and the steel core. Compared with traditional materials, it has good economic performance and meets the requirements of full life equipment cycle management, which is in line with the category of new materials, new processes, and new equipment. The service life of copper plated steel materials is 3 to 10 times that of traditional galvanized steel grounding materials.

2. High conductivity: If the conductivity of pure copper is taken as * * *, the conductivity of copper plated materials is between 20% and 40%, while the conductivity of traditional galvanized steel materials is 8.6%. Under the action of high-frequency grounding or lightning current, due to the skin effect of current, copper plated steel grounding materials have conductivity close to pure copper.

3. Easy installation: The horizontal copper plated steel grounding body is made of copper plated single core solid round steel, with a long single length and few intermediate connection points, making it easy to pass through pipes and bend; Vertical copper plated grounding material is easy and fast to install, saving time and effort without excavation. By connecting, any depth can be achieved and the underground aquifer can be utilized, resulting in significant resistance reduction effects. At the same time, there is no need to drill additional deep wells, thereby reducing the footprint of the substation.

4. Adhesion level of electroplating layer: Adopting electroplating technology, the density of current in all directions is consistent, and the copper layer adheres uniformly

Grounding systems are generally buried underground. Due to the complex soil environment, there are a large number of microorganisms and metal ions present, which can easily form a natural electrolytic environment and cause corrosion to metals. If the grounding body is severely corroded or even corroded and fractured, it will greatly affect the conductivity of the grounding grid. In addition, the grounding system is buried underground, making inspection and maintenance difficult. Therefore, the corrosion resistance of grounding materials directly determines the lifespan and cost of the grounding network. Usually, relevant departments and units stipulate that the service life of the grounding grid should be greater than the service life of the protected equipment, generally exceeding 50 years.

At present, commonly used grounding materials include galvanized steel materials, copper plated steel grounding materials, and pure copper materials. Depending on the region and environment, other metals can also be used as grounding materials, but their applications are not very common.